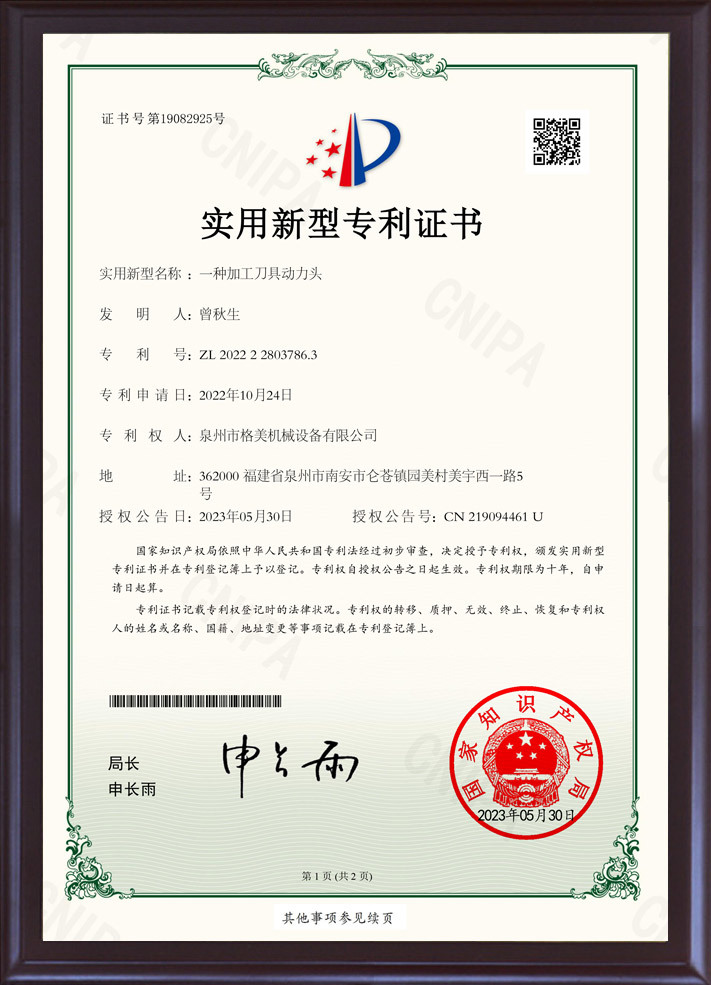

Quanzhou Gemei Machinery Equipment Co.,LTD

Our company is an automation equipment manufacturer integrating R & D, manufacturing and sales in all-in-one machines. The equipment is used in small hardware accessories that require mass production, and also supports customers to provide customized equipment for products. The equipment produced by Gemei Machinery has high precision, good stability, high-end atmosphere, compact structure, and simple operation. The company has complete technological development and innovation capabilities, and is equipped with high-tech talents to provide customers with high efficiency, low loss, and high quality automation. Processing plan.

Company to the quality of survival, in good faith and development, to create efficiency of service business philosophy. The company has been adhering to the principle that quality is the foundation of enterprise survival. Good at research and development and manufacture of various hardware CNC combination machine tools, used in mass production of hardware accessories.

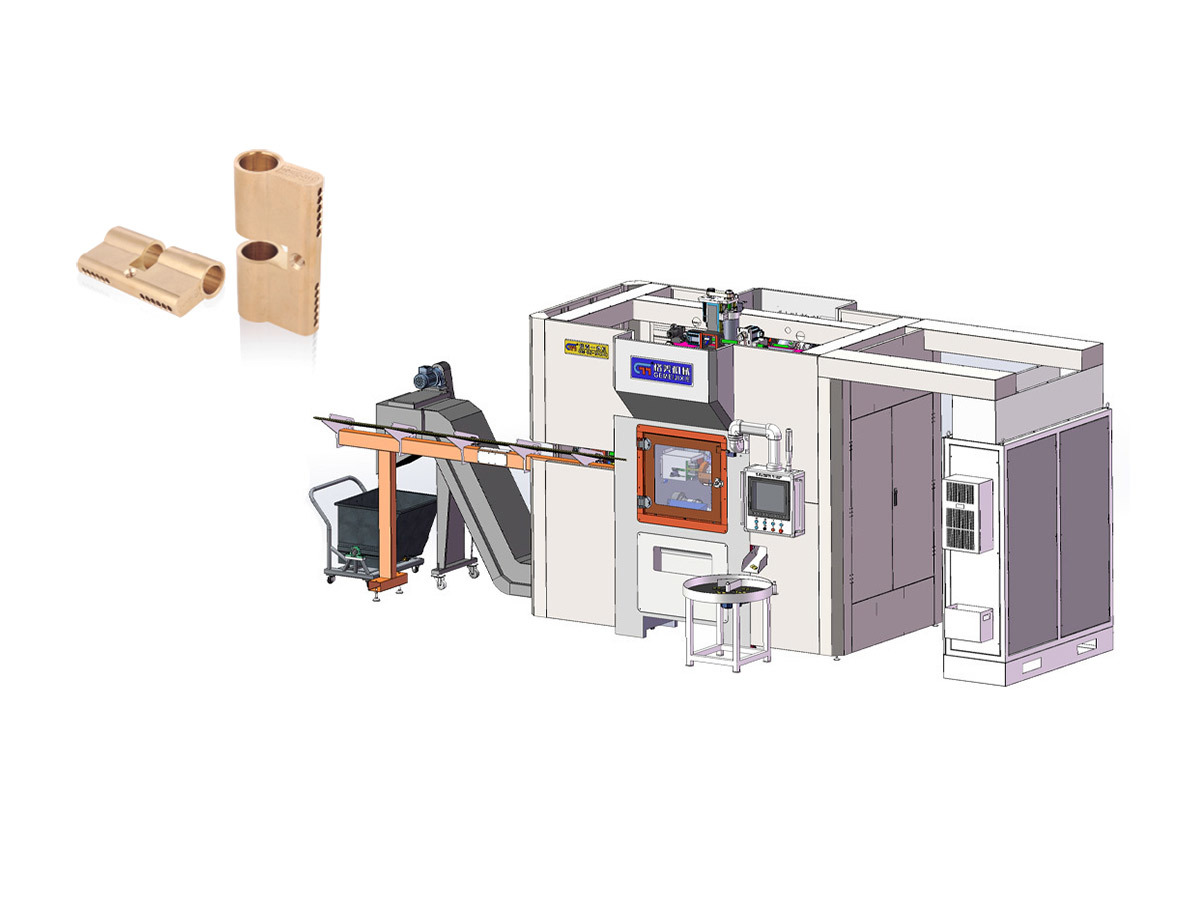

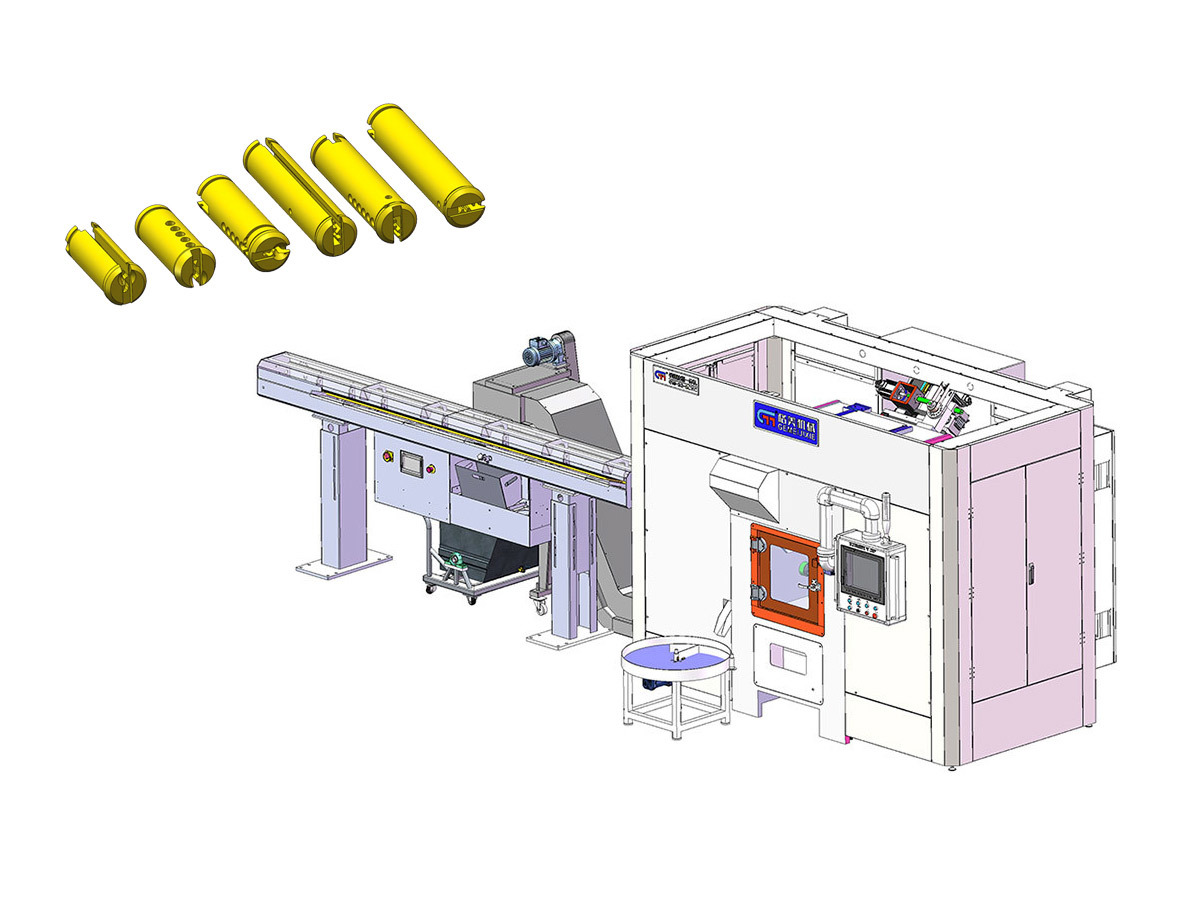

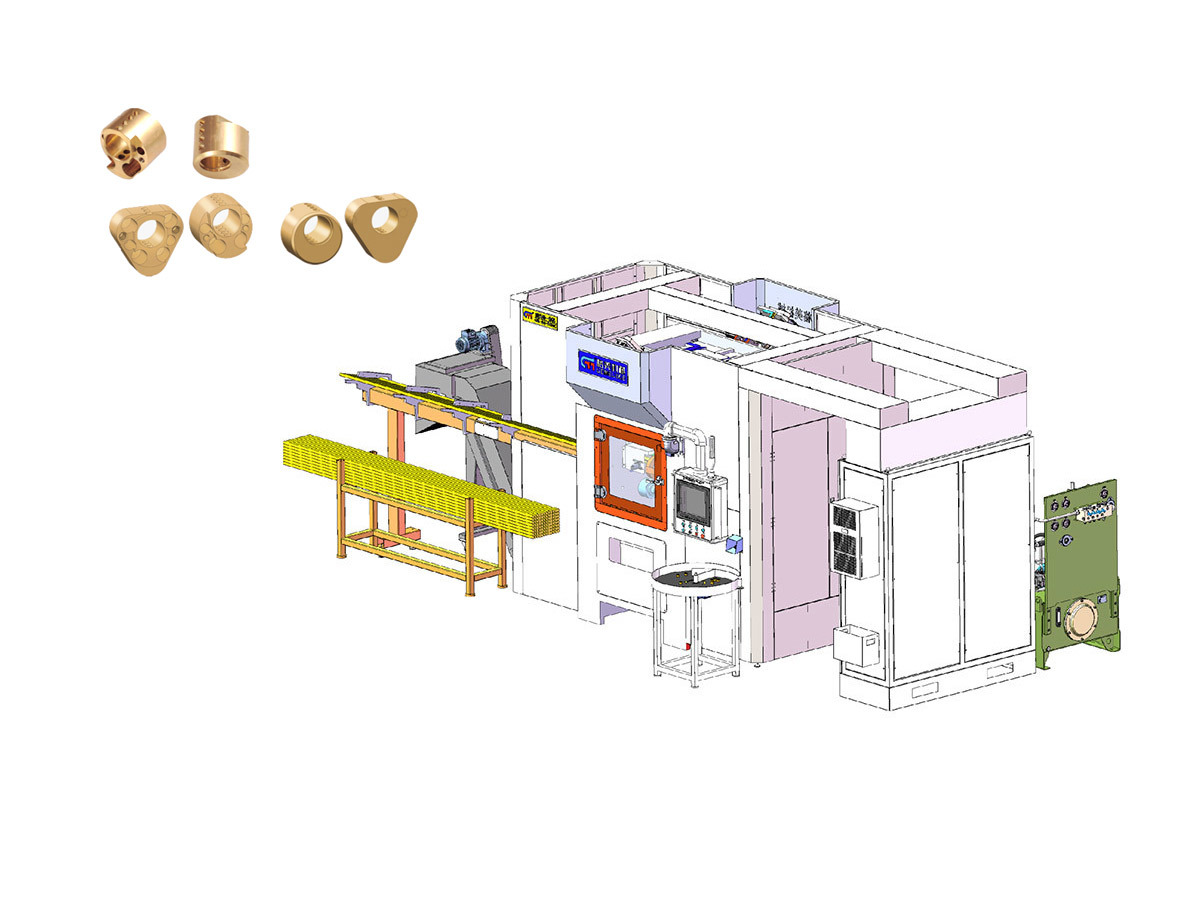

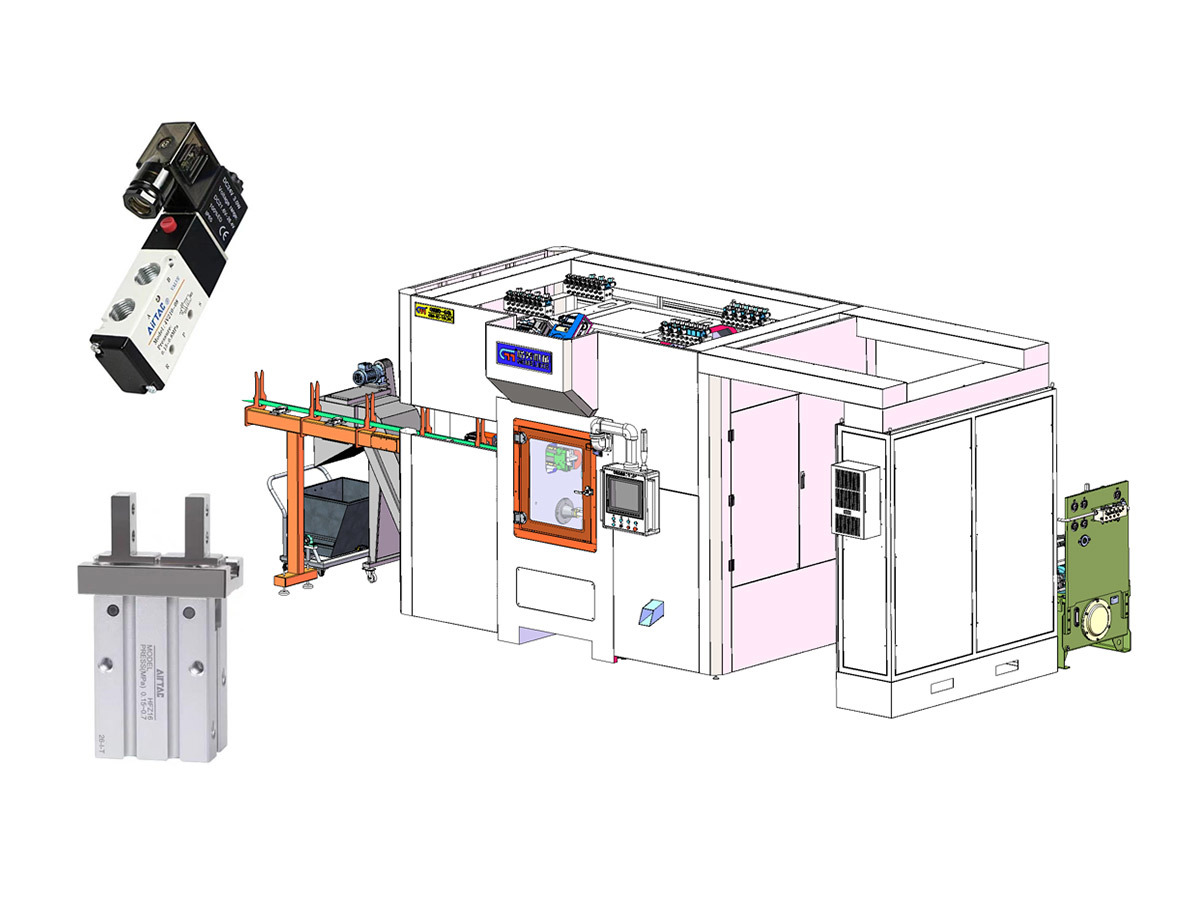

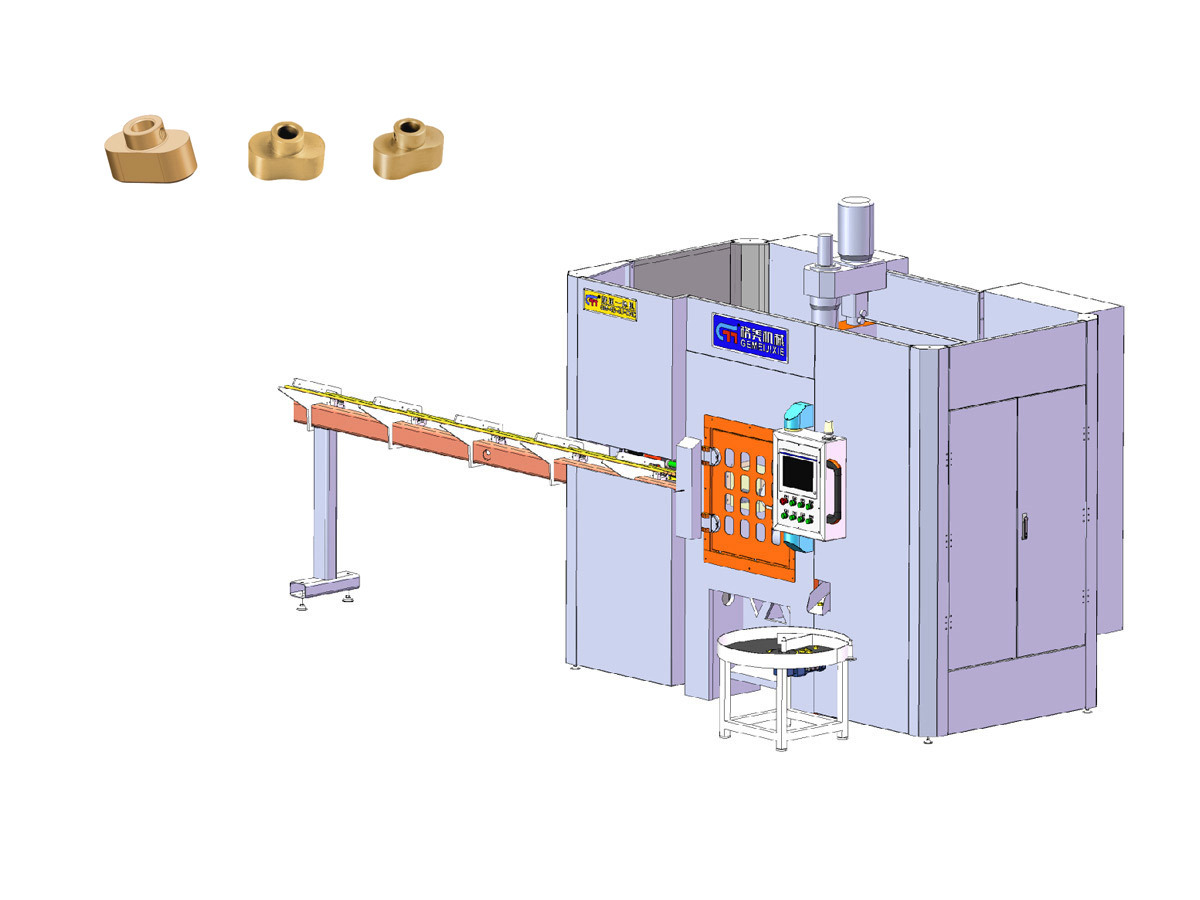

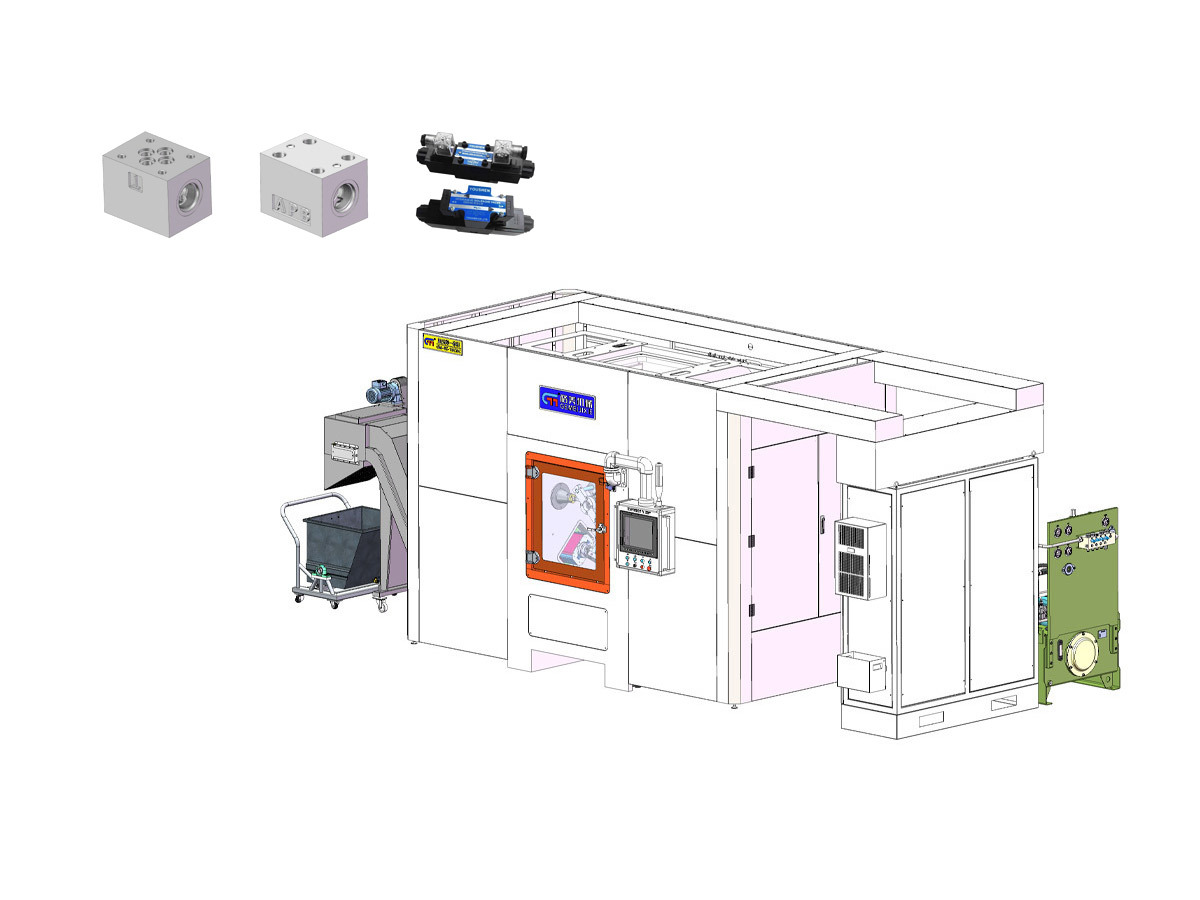

At present, the equipment we put into production in the market includes: all-in-one machine for locking gallbladder and groove; All-in-one machine for gourd lock shell and lock cylinder; All-in-one machine for padlock; All-in-one machine for knob and so on; All-in-one machine for water meter; Triangle valve all-in-one machine for ball valve and floating ball valve; All-in-one machine for fire sprinkler head and other equipment.

The company was created in 2020.

Serving more than 1000 customers

Products sold in more than 30 cities

Customer satisfaction

The company specializes in manufacturing all-in-one lock shell machine, gourd lock machine, round head lock cylinder machine, padlock machine, pneumatic solenoid valve machine, water meter machine, knob machine and other hardware processing machinery and equipment.

The company is located at the starting point of the "Maritime Silk Road" --- Quanzhou City, Fujian Province, is a wholly-owned enterprise

The company is located at the starting point of the "Maritime Silk Road"-Quanzhou City, Fujian Province, is a wholly-owned enterprise. The company has a complete technological development and innovation capabilities, with high-tech talent configuration, to become China's high-end equipment manufacturers. Company to the quality of survival, in good faith and development, to create efficiency of service business philosophy. The company has been adhering to the principle that quality is the foundation of enterprise survival. Good at research and development of various hardware CNC machine equipment, applied to mass production of hardware accessories.

Gemei mechanical equipment has high precision, good stability, high-end atmosphere, compact structure and simple operation, which provides high efficiency, low loss and high quality processing methods for enterprise manufacturing.

Leave us a message

If you have any comments or suggestions for us, please leave a message to us, we are your trusted partner!