Knob all-in-one machine

Knob integrated machine: It is suitable for working parts of bars, extruded bars and pipes. It adopts multi-channel CNC system servo motor to drive the rotating worktable, and the worktable drives 4 tooling synchronous fixtures to work at the same time, with high efficiency. Equipped with brushless servo motor-central encoder position control-locking table with hydraulic brake-synchronous hydraulic vise-drilling and tapping power head-double slide rail electric spindle cross slide table power head-cutting power head combination. Using PLC CNC programming control system, the operation is simple and convenient. This machine multi-process synchronous processing, stable quality, can replace more than one ordinary equipment. One person can operate 3-5 devices at the same time, which saves time and effort, and improves efficiency and reduces costs for enterprises.

Product Classification:

Details

Machine Introduction

____

Knob integrated machine: It is suitable for working parts of bars, extruded bars and pipes. It adopts multi-channel CNC system servo motor to drive the rotating worktable, and the worktable drives 4 tooling synchronous fixtures to work at the same time, with high efficiency. Equipped with brushless servo motor-central encoder position control-locking table with hydraulic brake-synchronous hydraulic vise-drilling and tapping power head-double slide rail electric spindle cross slide table power head-cutting power head combination. Using PLC CNC programming control system, the operation is simple and convenient. This machine multi-process synchronous processing, stable quality, can replace more than one ordinary equipment. One person can operate 3-5 devices at the same time, which saves time and effort, and improves efficiency and reduces costs for enterprises.

In the ever - evolving landscape of technology, a remarkable innovation has emerged - the Knob all-in-one machine. This state - of - the - art device is set to transform the way we approach various tasks, offering a seamless blend of multiple functions in a single, compact unit.

The Knob all-in-one machine is designed with versatility in mind. At its core, it features an intuitive knob interface that serves as the control center for a multitude of operations. This unique design element not only simplifies user interaction but also adds a touch of elegance to the overall device.

One of the most impressive aspects of this machine is its all - in - one functionality. It combines features such as printing, scanning, and copying, eliminating the need for multiple separate devices. For small businesses and home offices, this means significant savings in terms of both space and cost. The printing capabilities are top - notch, delivering high - quality prints with sharp details and vivid colors. Whether it's text documents or high - resolution images, the Knob all - in - one machine can handle them with ease.

Scanning with the Knob all - in - one machine is a breeze. The device is equipped with advanced scanning technology that can quickly and accurately digitize documents. It supports various file formats, making it convenient for users to store and share their scanned files. Additionally, the copying function is equally efficient, reproducing documents with great fidelity.

In terms of connectivity, the Knob all - in - one machine offers a range of options. It can be easily connected to computers, laptops, and even mobile devices via Wi - Fi or USB. This allows for seamless sharing of files and remote control of the machine's functions. For example, users can start a printing job from their smartphones while on the go, adding a new level of convenience to the user experience.

The device also comes with user - friendly software that further enhances its usability. The software provides an intuitive interface for managing all the functions of the all - in - one machine, from adjusting print settings to organizing scanned documents. It also offers features such as automatic duplex printing, which not only saves paper but also showcases the machine's environmentally - friendly design.

Furthermore, the Knob all-in-one machine is built to last. Its robust construction and high - quality components ensure reliable performance over time. Maintenance is also made easy, with accessible parts and clear instructions for routine upkeep.

As more and more consumers and businesses look for efficient, multi - functional devices, the Knob all-in-one machine is poised to make a significant impact. It represents a new generation of all - in - one devices that combine functionality, ease of use, and style in one remarkable package. Whether for personal use at home or for professional applications in the office, this machine is set to become an indispensable tool in the modern digital age.

Process flow

____

Automatic feeding-blanking-cutting-forming of outer circle and inner hole-cylinder positioning-milling end face, chamfering-drilling and tapping-cylinder positioning-automatic blanking.

Knob machine running video

____

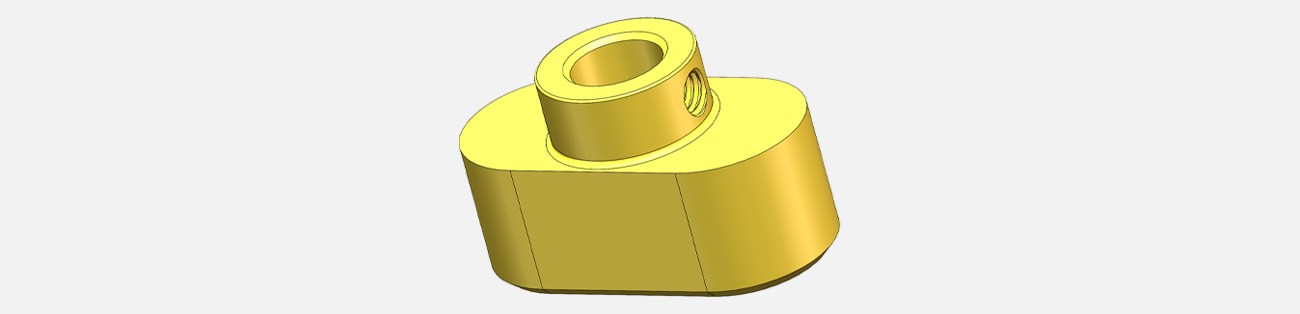

processing case

____

Beat: 12-17 seconds one

Machine Parameters

____

| Processing materials | Copper | Processing range | 40mm-130mm |

| Work efficiency | 12s-17s/unit | Machine Dimensions | 6.5mX2.8mX2.6m |

| machine net weight | Machine power | 72kw | |

| Air pressure | 0.4-0.6Mpa | Oil pressure | 2-8Mpa |

Machine Configuration

____

1. System control: Yitu, Xinjie

2. Pneumatic accessories: Yadke

3. Electrical accessories: ABB

4. Bearing: Harbin shaft

5. Servo motor: Yitu, Xinjie

6. Ball screw: Taiwan TBI

7. Hydraulic system: Taiwan

Related Products

Message consultation

Please leave your email and our professionals will contact you as soon as possible!