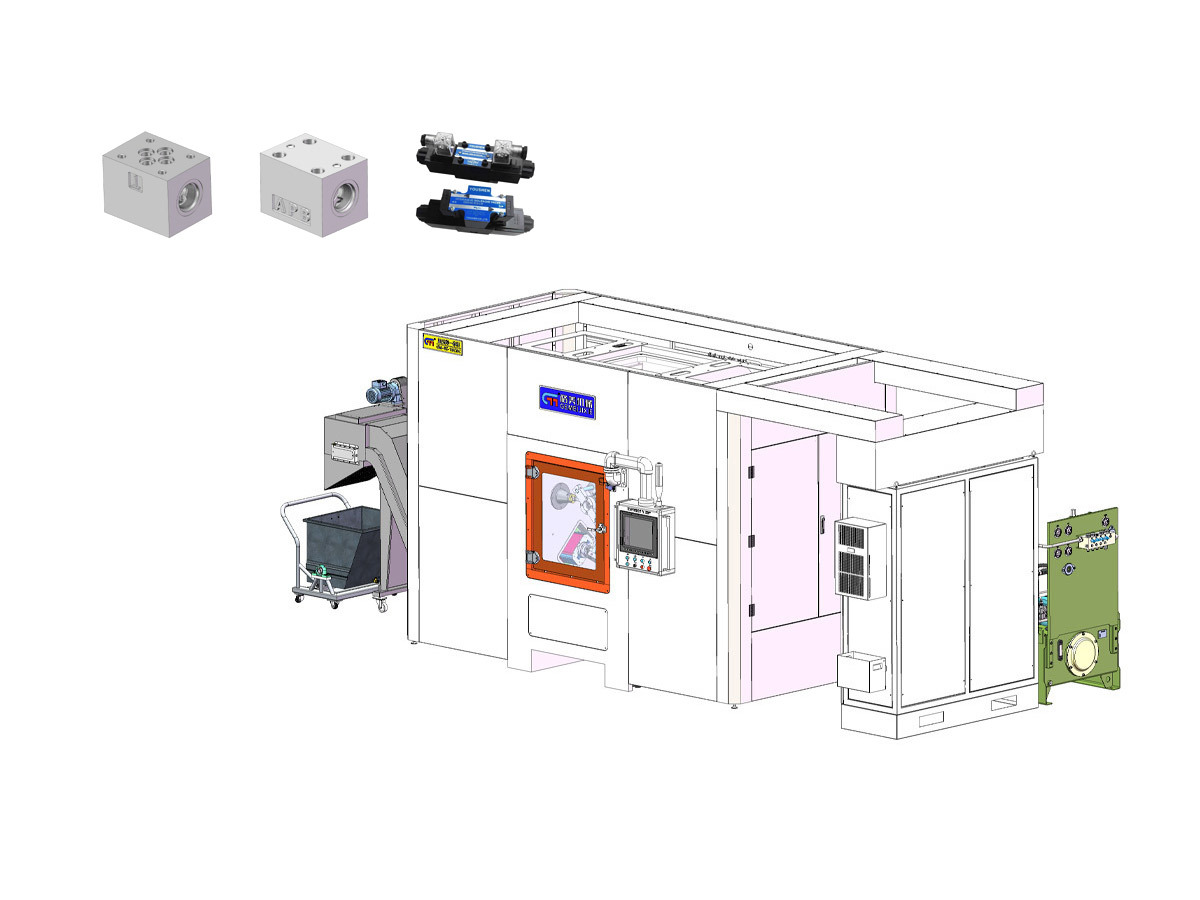

(2)Oil pressure solenoid valve all-in-one machine,floating ball valve all-in-one machine

Hydraulic solenoid valve integrated machine: suitable for working parts of cast billet and forging billet. The servo motor of multi-channel numerical control system is used to drive the rotating worktable. The worktable drives 8 rotating tooling synchronous fixtures to work at the same time. The workpiece is processed at one time with high efficiency. Equipped with brushless servo motor-central encoder position control-locking table with hydraulic brake-synchronous hydraulic rotating fixture, outer diamond drilling power head, outer diamond spreading power head and outer diamond 3 linkage power head. Using PLC CNC programming control system, the operation is simple and convenient. This machine multi-process synchronous processing, stable quality, can replace more than one ordinary equipment. One person can operate 3-5 devices at the same time, which saves time and effort, and improves efficiency and reduces costs for enterprises.

Product Classification:

Details

In the world of valve manufacturing, a new star has emerged - the floating ball valve all-in-one machine. This innovative piece of machinery is set to redefine the production process of floating ball valves.

Manufacturers in China, known for their advanced manufacturing capabilities, are at the forefront of producing these all - in - one machines. These machines are of the best quality, incorporating advanced technology that ensures precision and durability.

The floating ball valve all-in-one machine offers a cost - effective solution for valve production. It is designed to be highly efficient, which helps in reducing production costs. For companies looking for cheap yet high - quality production equipment, this machine is an ideal choice.

One of the key floating ball valve all-in-one machine is its ability to produce the newest and most innovative floating ball valve designs. It can handle various customization requirements, whether it's for a specific size, shape, or performance specification. This makes it suitable for both OEM and customized production needs.

Chinese suppliers of this machine are also offering great deals. They provide detailed quotations and pricelists, enabling customers to make informed decisions. With wholesale options available, larger - scale manufacturers can take advantage of economies of scale.

These all - in - one machines are also produced by factories that adhere to CE certification standards. This ensures that the machines are not only of high quality but also meet international safety and performance requirements.

Many of these machines are in stock, allowing for quick delivery. Some suppliers even offer free samples of their floating ball valve all - in - one machines for potential customers to test.

The floating ball valve all-in-one machine is also known for its fancy and classy design. It is built to last, with durable components that can withstand the rigors of continuous production. Famous Chinese manufacturers are leading the way in this area, and their machines are being exported all over the world.

In conclusion, the floating ball valve all-in-one machine is a remarkable product that combines quality, efficiency, and cost - effectiveness. Whether you are a small - scale manufacturer or a large - scale industrial player, this machine from Chinese manufacturers, suppliers, and exporters is worth considering for your floating ball valve production needs.

Machine Introduction

____

Hydraulic solenoid valve integrated machine: suitable for working parts of cast billet and forging billet. The servo motor of multi-channel numerical control system is used to drive the rotating worktable. The worktable drives 8 rotating tooling synchronous fixtures to work at the same time. The workpiece is processed at one time with high efficiency. Equipped with brushless servo motor-central encoder position control-locking table with hydraulic brake-synchronous hydraulic rotating fixture, outer diamond drilling power head, outer diamond spreading power head and outer diamond 3 linkage power head. Using PLC CNC programming control system, the operation is simple and convenient. This machine multi-process synchronous processing, stable quality, can replace more than one ordinary equipment. One person can operate 3-5 devices at the same time, which saves time and effort, and improves efficiency and reduces costs for enterprises.

Process flow

____

Discharging, milling plane (4 sides), drilling Ф 5.5 mounting holes (4), drilling M4 thread countersunk head bottom holes (2), large hole rough machining (both sides), drilling oil discharge holes (4), drilling Ф 9.5 mounting countersunk head holes (4), large hole finishing (both sides), turning M20X1 teeth (both sides), milling large hole inner groove, tapping M4 thread (2), blanking.

processing case

____

Beat: 20 seconds a

Machine Parameters

____

| Processing materials | cast iron | Processing range | 50mm-120mm |

| Work efficiency | 20s/unit | Machine Dimensions | 6.7m × 2.9m × 2.6m |

| machine net weight | Machine power | 50kw | |

| Air pressure | 0.4-0.6Mpa | Oil pressure | 2-8Mpa |

Machine Configuration

____

1. System control: Yitu, Xinjie

2. Pneumatic accessories: Yadke

3. Electrical accessories: ABB

4. Bearing: Harbin shaft

5. Servo motor: Yitu, Xinjie

6. Ball screw: Taiwan TBI

7. Hydraulic system: Taiwan

Related Products

Message consultation

Please leave your email and our professionals will contact you as soon as possible!